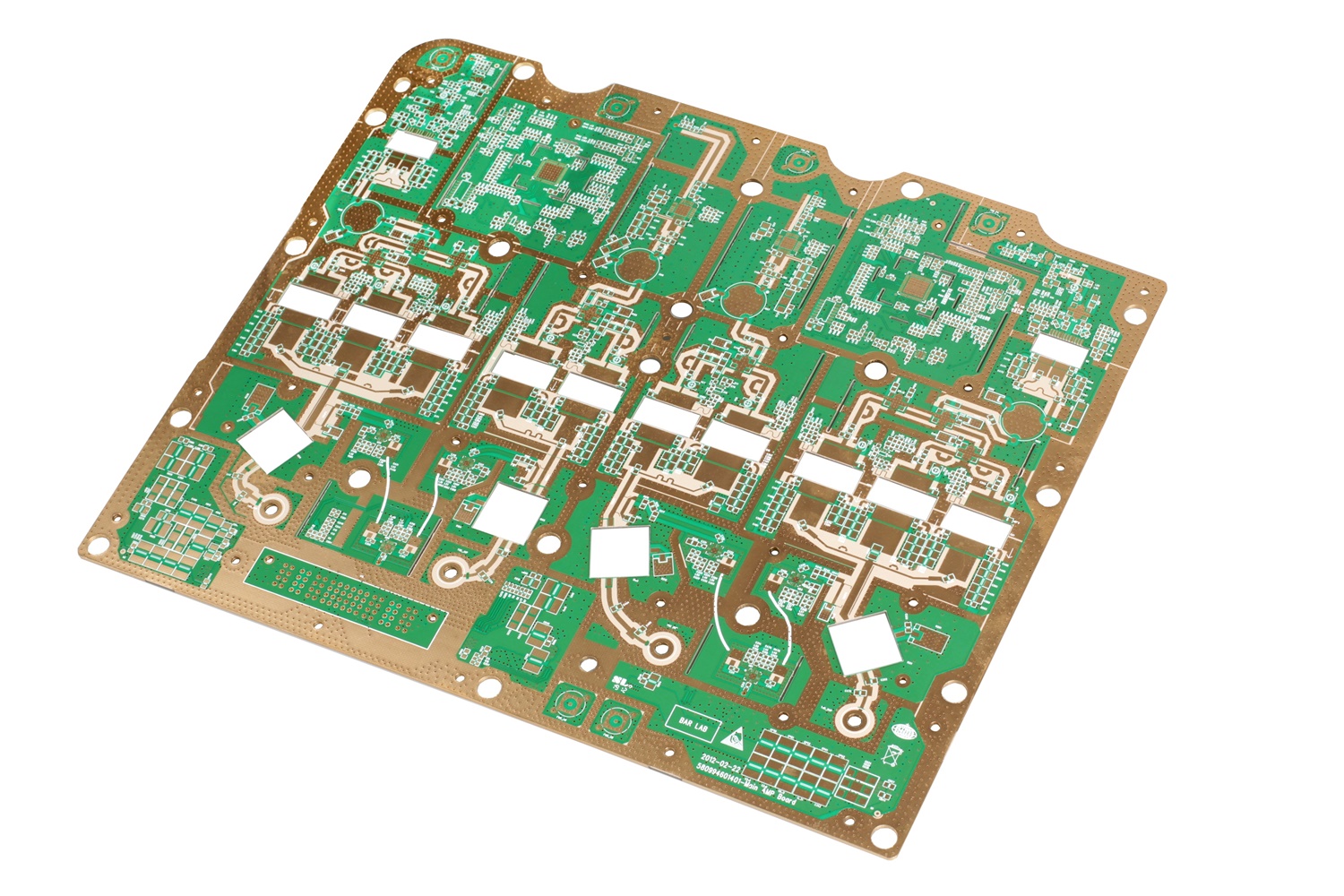

High frequency pcb materials

1.FR-4

When selecting a PCB substrate for high frequency circuits, pay special attention to the materials used. For many years, the standard circuit board material currently used in the market has been FR-4, a flame-retardant type 4 woven glass-reinforced epoxy laminate. This high frequency pcb materials are very cost effective and easy to use, making it ideal for high frequency pcb manufacturers as FR-4 material. It is also a perfect electrical insulator and a robust material for printed circuit boards.

2.Rogers, Isola, Taconic, Dupont, and Megatron

If there are a requirement for high frequency pcb in terms of signal transmission at high speed or characteristic impedance control requirements. In this case, the focus is on the DF and its performance under frequency, temperature, and humidity conditions. The choice of PCB board must be to meet the design requirements, mass production, cost in the middle to strike a balance.

In simple terms, the design requirements include the electrical and structural reliability of the two parts. Usually, in designing a very high-speed PCB board (greater than GHz frequency), the board issue will be more important. For example, now commonly used FR-4 material, in several GHz frequency dielectric loss Df (Dielectricloss) will be very large, may not be suitable.The most common high frequency pcb are Rogers, Isola, Taconic, Dupont, and Megatron materials. All of these materials typically have low Dk and low loss.

3.Teflon and flexible substrates

In terms of price, FR4 is the cheapest compared to dedicated high-speed materials and Teflon, with Teflon being the most expensive. However, the performance of FR-4 starts to degrade when the signal speed exceeds 1.6 GHz. Therefore, DK, Df, water absorption, environmental survivability, next-generation substrates, Teflon, and flexible circuits are the best choices.

If a printed circuit board requires frequencies above 10 GHz, next-generation substrates, Teflon, and Flex substrates are your best choices because they are far superior to traditional FR-4 materials. Another consideration for making high frequency pcb is the moisture absorption rate of the material used in the board.

Even a tiny amount of moisture can change the electrical properties of a high frequency circuit. Traditional FR-4 can absorb up to 50% moisture, while high frequency pcb materials such as PTFE can absorb as little as 2%. That’s why high frequency pcb manufacturers generally choose FR-4 materials first.

Other news about S&L

- Scan to Discover Your Past Life? See How PCB Factories Use Traceability Systems to Create a Quality

- Joining Hands with AI to Forge the New Future of Smart Manufacturing at Sun&Lynn Circuits

- Sun&Lynn Circuits CO., Ltd. was invited to attend the Sixth Global Customs AEO Conference!

- Celebrating the Establishment of SUNLYNN CIRCUITS(THAILAND)

- Good News! Sun&Lynn Circuits Co.,Ltd. is honored as one of the Top 100 Innovative Enterprises in Bao

- What Should You Know about Metal Core PCB?

- FPC supplier : the types of Flexible PCB

- PCB manufacturer China:Why PCB board snake line, what is it used for?

- What is Metal Core PCB and types of Metal Core PCB?

- Why are High frequency PCBs much more expensive than normal PCBs?

Your browsing history

- Preparing Your Design for High Frequency PCB Layout

- Flexible PCB manufacturer:What is PCB Etching

- BYD awarded S&L as excellent PCB supplier of continuous improvement

- Celec electric technology

- What is High frequency PCB V-Scoring

- FLEX RIGID PCB:AUTOMATION, REPLACES JOBS BUT CREATES OTHER OPPORTUNITIES

- FPC supplier:Factors that need to consider when using a custom FPC thickness

- Flex Rigid PCB vs. A Flexible Circuit

- PCB factory china Challenges—Improve Your Switched-mode Power Supply Designs

- Health care PCB:HOW TO ACHIEVE BETTER SIGNAL TRANSMISSION DURING PCB DESIGN

A total of -comments【I want to comment】