Flexible PCB manufacturer:Why Buy Flexible PCB Board?

FlexiblePCBmanufacturer talked,Printing technology is improving all the time, and more options are appearing before our eyes, so why should you buy a flex PCB for your project?What are its advantages?Which projects need it more?

Advantages of Flexible PCB

· Flexibility allows for extended uses among a variety of products across industries

· Less risk of wire connection failure increases overall reliability

· Reduction in size and weight compared to rigid boards

· Good temperature range makes flex PCBs suitable for harsher environments

· High Circuit Density

PCBsupplier talk Application of Flexible PCB

Flexible printed circuit boards are suited to a variety of situations where rigid circuit boards.

Consumer Electronics

Flex PCB has a wide range of applications in electronics. Some of the devices that use this flex PCB include laptops, cameras, flip cell phones, calculators, etc.

FPC for mobile phone

Automotive

Flex PCB in the automotive industry not only increases reliability but also helps in weight saving compared to traditional PCB designs. Weight saving is one of the best methods of saving fuel; thus, flex PCB helps reduce the labor involved in the manufacturing of vehicles. While on the other hand, the flex PCB's resistance to vibrating makes them better for harsh environments. Some application areas of flex PCB in the automotive area include GPS, engine control, airbag systems, and antilock system.

FPC for GPS

Medical

There has been a growing number of uses of PCBs with the advancement in technology in the healthcare industry. Flex PCBs are essential for medical applications as circuits must withstand extreme conditions in the human body. Some medical devices that use this flex PCB include pacemakers, hearing aids, exercise monitors, heart monitors, etc. In addition, the PillCam, a swallowable pill camera, uses a durable and non-toxic super-fine flex circuit.

Researchers are not developing the process for printing the circuit in the flexible and organic material for body implants. This material is even more flexible and efficient.

FPC for Medical instrument

Industrial

Flex PCBs can operate in stressful conditions and allow for machine design flexibility. In the industrial sector, the flex PCB is used in radio frequency communication, power circuits, industrial automation, etc. Using flex PCB opens up the door for various industrial spaces.

FPC for Industrial equipment

Aerospace

Flex-rigid PCBs improve the reliability of industrial equipment and allow for more flexible machinery design. Its other applications include radio frequency communications, power distribution, and control circuits. In addition, compared to rigid boards, flex-rigid boards allow sensors to be much smaller and thinner.

Military

The military is a sector that demands high performance with high precision PCB design. These PCBs must go through quality checks at each stage, starting from the fabrication of PCB, assembly, and final deployment of the product. Various factors influence the development process of military PCBs.

Power Electronics

The flexibility and thinness of copper are also benefits of flexible printed circuit boards, which make them capable of handling heavy power currents. It is particularly important for devices in the power electronics industry, which require more power to operate fully.

High-Speed Digital, RF, and Microwave Applications

FPC is so reliable for handling high-frequency signals.

Other news about S&L

- Sun&Lynn Circuits CO., Ltd. was invited to attend the Sixth Global Customs AEO Conference!

- Celebrating the Establishment of SUNLYNN CIRCUITS(THAILAND)

- Good News! Sun&Lynn Circuits Co.,Ltd. is honored as one of the Top 100 Innovative Enterprises in Bao

- What Should You Know about Metal Core PCB?

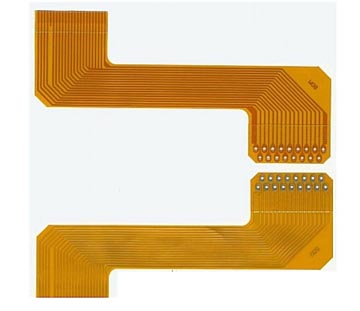

- FPC supplier : the types of Flexible PCB

- PCB manufacturer China:Why PCB board snake line, what is it used for?

- What is Metal Core PCB and types of Metal Core PCB?

- Why are High frequency PCBs much more expensive than normal PCBs?

- Flexible PCB supplier China :When to use flexible PCB?

- Flexible PCB manufacturer:What Is Flex Soldering?

Your browsing history

- PCB supplier china:Common Issues Affecting A PCB

- PCB manufacturer China How to choose which surface treatment for pcb

- EVOC

- Flexible PCB supplier china tells you the elements to be Considered in FPC Material Selection

- FPC supplier:What is Trace Width

- Flexible PCB supplier china :Use Huawei Software? ! Volkswagen's response

- How to corerct solder balls before occurrence for Health care PCB

- PCB supplier China:The Apple Vision Pro AR and VR headset is a reality

- Commscope

- What Health care PCB defects can be detected by X-rays

A total of -comments【I want to comment】